Product Development

With over 150 years of cumulative medical device design experience, we have developed products ranging from intravenous infusion devices to cardiovascular implants. We have created a variety of disposable and resposable devices, reusable instrumentation, and capital equipment.

Often starting with just an idea or a clinical issue in need of an engineering solution, our prototypes come complete from a team that understands medical needs and market conditions.

Jump to our prototyping capabilities

Our team combines innovative design, experience-based intuition, and market knowledge to produce solutions that work as intended, on time and in budget.

We have proven experience managing critical milestones as part of venture start-ups.

Flex fully appreciates expenditure limits and investor demands on cost controls. Every team member takes budgets very seriously and is experienced at succeeding with strict time and cost constraints.

Our Design Specialty Areas

Cardiovascular Surgery

General Surgery

Orthopedics

Critical Care Medicine

Interventional Cardiology

Urology

Gastroenterology

Obstetrics & Gynecology

Vascular Surgery

Diagnostic Imaging

Plastic Surgery

Why outsource with Flex?

On demand engineering: Utilize a dedicated engineering team when you need it.

Flex can work in parallel or independently

Explore alternate concepts and solutions

Save on cost of recruiting and managing new engineers to explore new product ideas

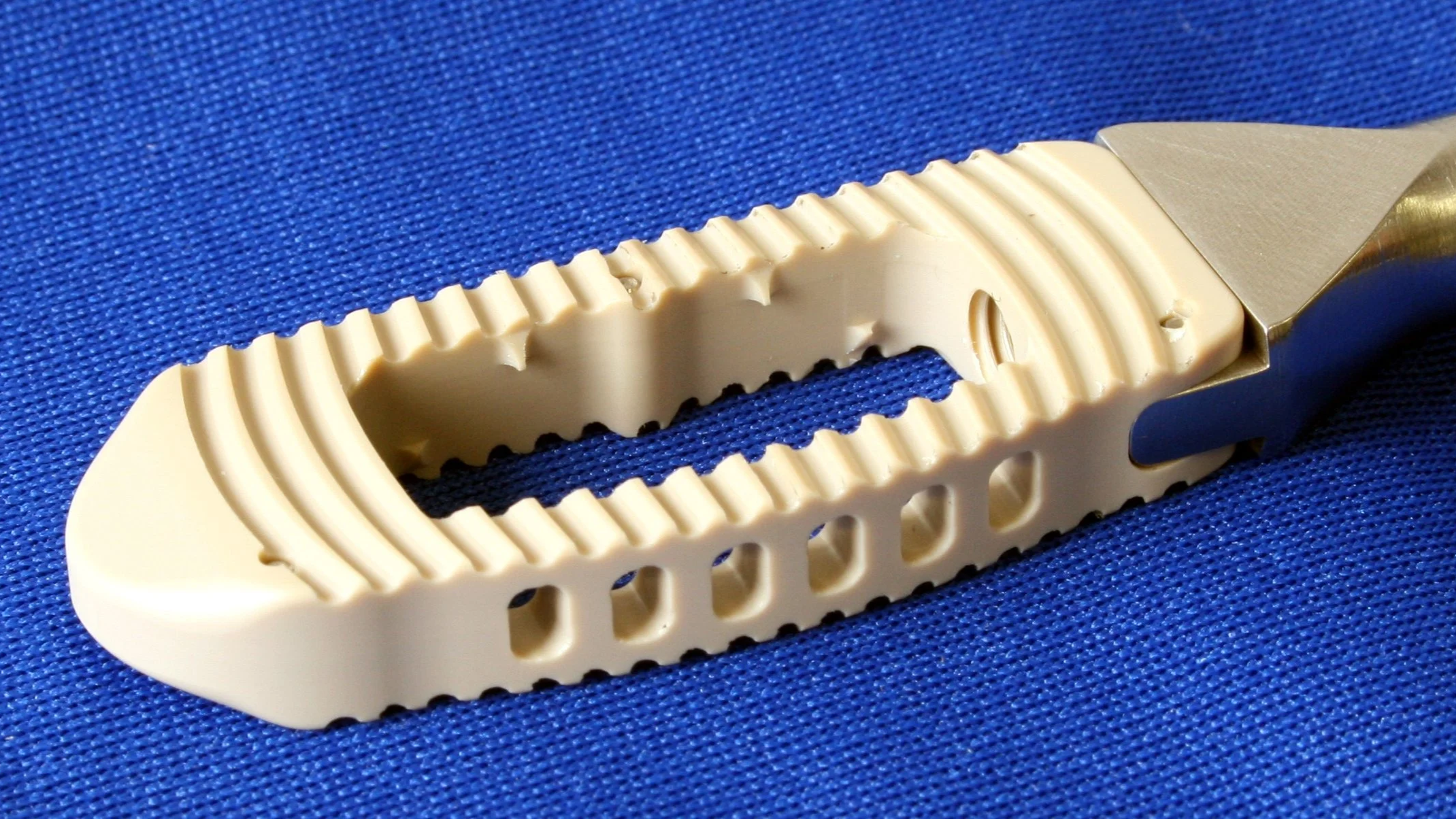

Prototyping Capabilities

State of the art machine shop with lathes, mini-lathes, CNC mills, and laser cutting equipment.

Precision micro-machining

Extensive material selection including Stainless Steel, Aluminum, Titanium, PEEK, Acetal, Ultem, and more.

Thin sheet thermoforming

Thin film welding

Microfluidic chips

Nitinol forming and shape setting

FDM and SLA 3D printing

Silicone molding

Dip molding

Textiles / wearables

Small scale injection molding

Miniature sheet metal

Tube bending and forming

Metrology

Mechanical testing and verification

Finite element analysis